The QY3S Series hardened gear reducer is a next-generation product, based on the classic QJ series for cranes, featuring a comprehensive upgrade with modern design and advanced manufacturing processes. Designed specifically for heavy-load, high-frequency, and high-impact applications such as cranes and hoists, it adheres to the core design principles of high reliability, long life, and low maintenance, making it an ideal choice for modern industrial heavy-duty transmissions.

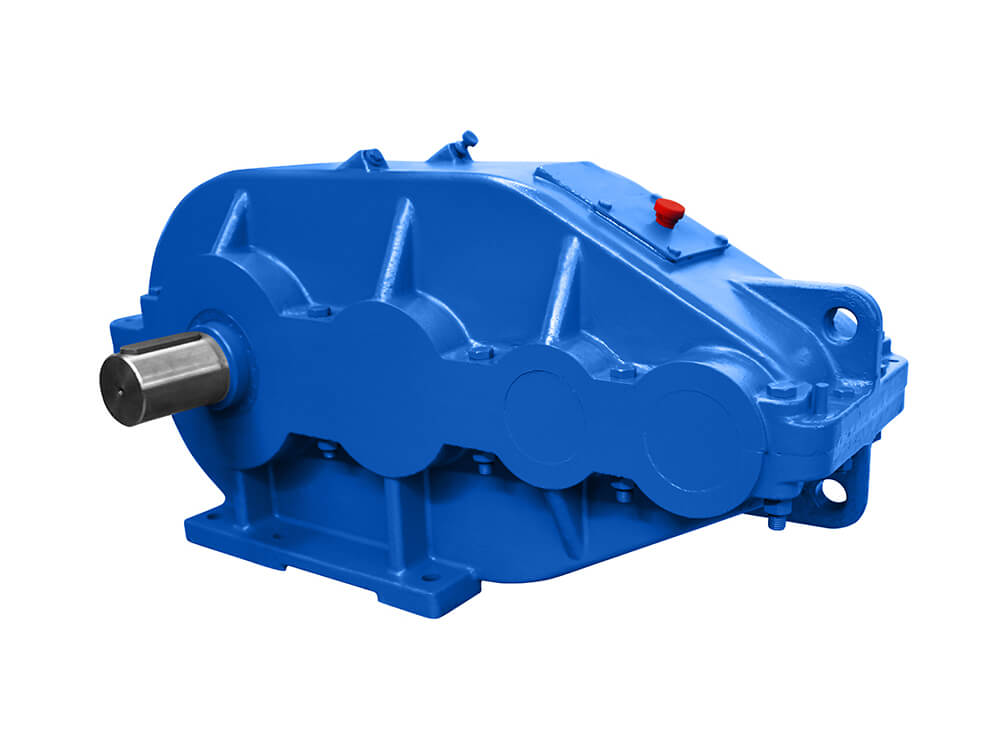

QY3S Series Hardened Gear Reducer

Description

The QY3S Series hardened gear reducer is a next-generation product, based on the classic QJ series for cranes, featuring a comprehensive upgrade with modern design and advanced manufacturing processes. Designed specifically for heavy-load, high-frequency, and high-impact applications such as cranes and hoists, it adheres to the core design principles of high reliability, long life, and low maintenance, making it an ideal choice for modern industrial heavy-duty transmissions.

Core Design and Manufacturing Process

We understand that superior performance stems from meticulous attention to detail.

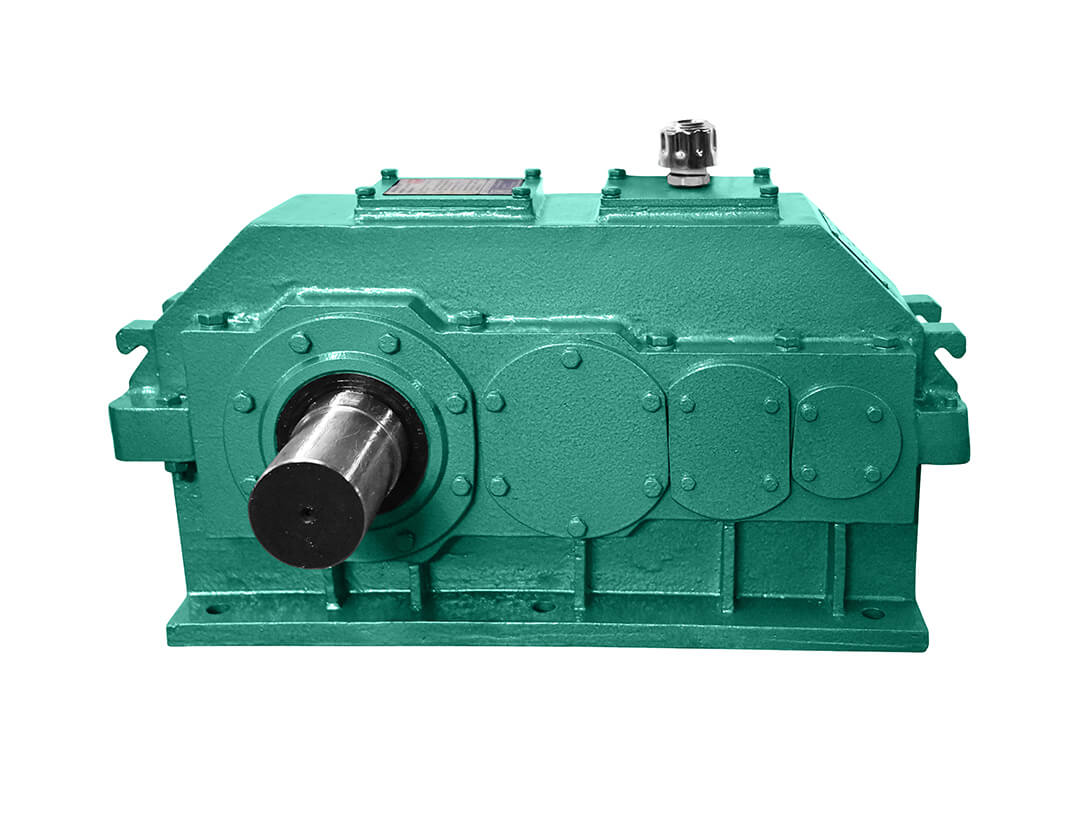

High-Strength Housing Structure

Material and Craftsmanship: The housing is welded from high-quality steel plates, offering greater strength and toughness than traditional cast housings.

Stress Relief: After welding, the housing undergoes an annealing treatment to effectively eliminate internal stresses, minimizing the risk of deformation and cracking during operation and ensuring long-term operational stability.

Precision Machining: Single-stage clamping and machining on a CNC boring and milling center ensures high precision and concentricity of the bearing bore and mounting surfaces, laying a solid foundation for smooth gear transmission.

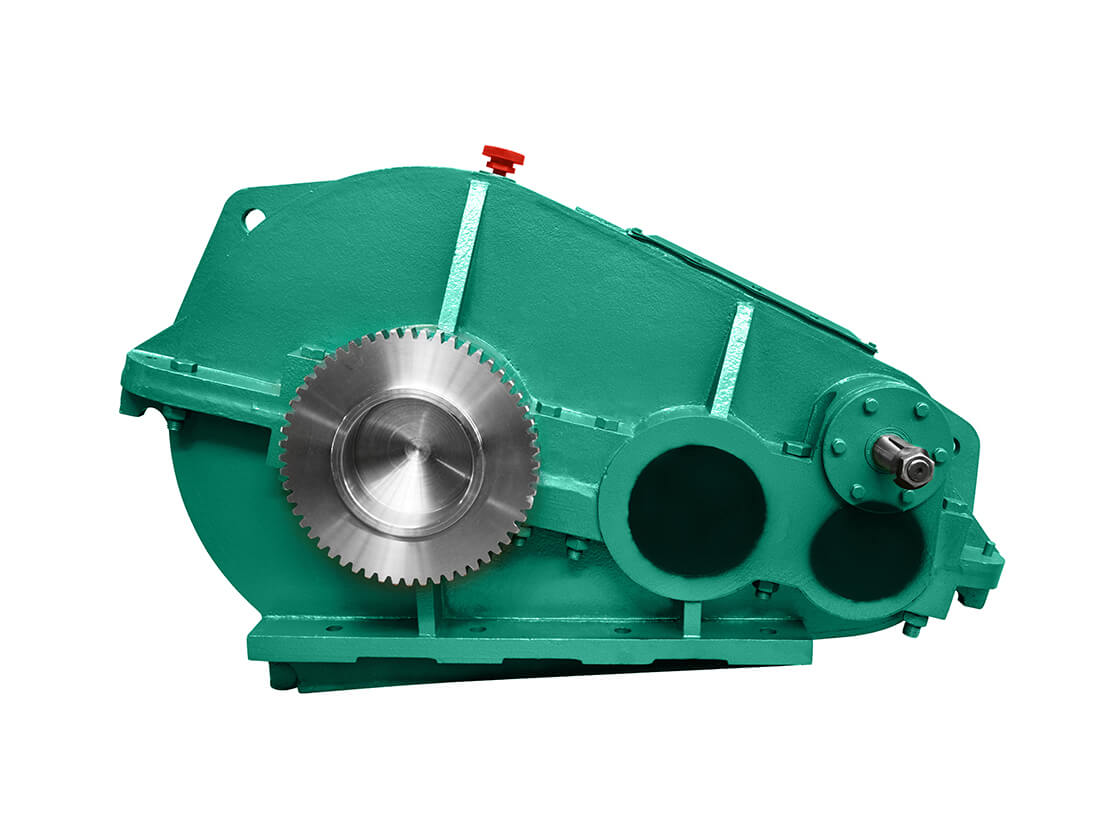

Top-tier Gear Manufacturing Standards

High-Quality Materials: Gears are made of high-quality low-carbon alloy steel (such as 20CrMnTi), offering uniform material quality and excellent toughness, capable of withstanding significant impact loads.

Core Heat Treatment: The tooth surfaces undergo carburizing and quenching to form a deep, high-hardness (HRC58-62) wear-resistant layer, while maintaining excellent toughness in the core. This creates an optimal combination of "hard tooth surface, tough core" for excellent pitting and wear resistance.

Precision Forming: Final grinding of the gears is performed on a high-precision gear grinding machine in a constant temperature workshop. This not only corrects minor distortion after heat treatment but also achieves gear precision of national standard Grade 6 or higher, ensuring smooth transmission, low noise, and high efficiency.

Product Advantages Summary

Higher Load Capacity: Hardened tooth surface technology enables higher torque per unit volume and a more compact structure.

Longer Service Life: Excellent wear resistance and fatigue resistance significantly extend overhaul intervals and service life.

Smoother Operation: High-precision gear manufacturing ensures smooth transmission, low vibration, and low noise.

Higher Safety and Reliability: Comprehensive quality control throughout the entire process, from materials to process, ensures stable performance under harsh operating conditions.

Lower Maintenance Cost: Long service life and low failure rate save users significant maintenance time and costs.

Main Applications

This series of reducers is widely suitable for various types of lifting and transportation machinery, such as:

Various types of bridge and gantry cranes

Tower cranes

Port container cranes

Winches and hoists

Other heavy material handling equipment