The ZSC series vertical soft tooth surface reducer is a vertically mounted three-stage cylindrical gear reducer designed for industrial applications requiring vertical power transmission in confined installation spaces. Featuring a compact structure, a wide speed ratio range, and high load capacity, this series is widely used in medium-sized equipment in industries such as lifting, metallurgy, mining, and construction.

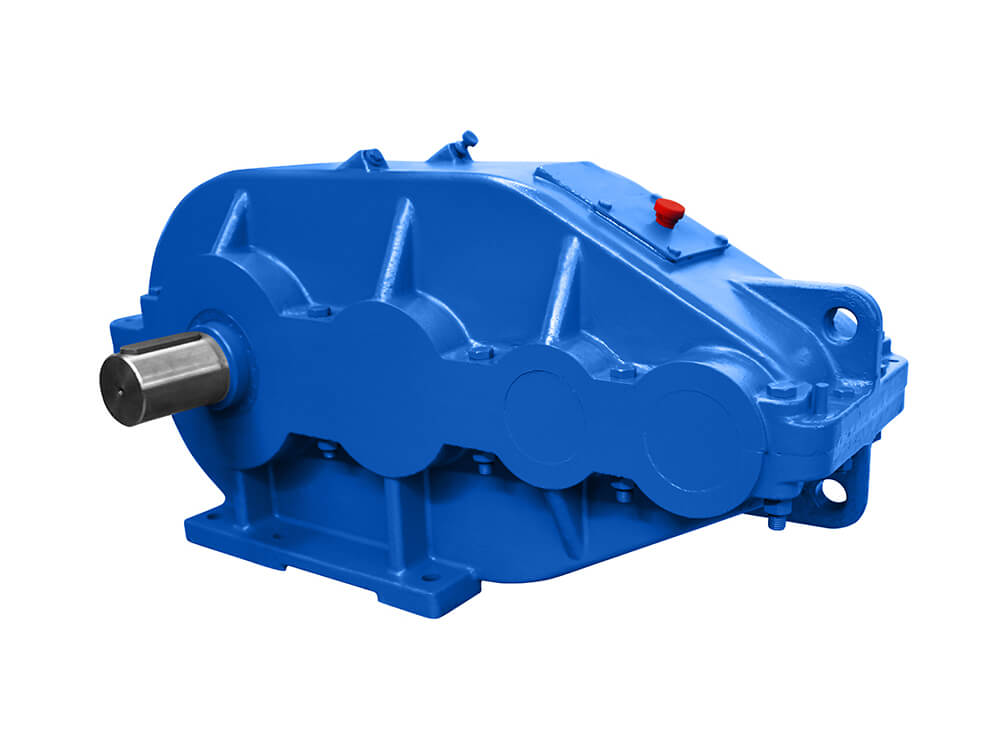

ZSC Series Vertical Soft Tooth Surface Reducer

Description

The ZSC series vertical soft tooth surface reducer is a vertically mounted three-stage cylindrical gear reducer designed for industrial applications requiring vertical power transmission in confined installation spaces. Featuring a compact structure, a wide speed ratio range, and high load capacity, this series is widely used in medium-sized equipment in industries such as lifting, metallurgy, mining, and construction.

The ZSC(A) series is an upgraded version of the ZSC, further optimizing performance while maintaining dimensional compatibility.

Product Features

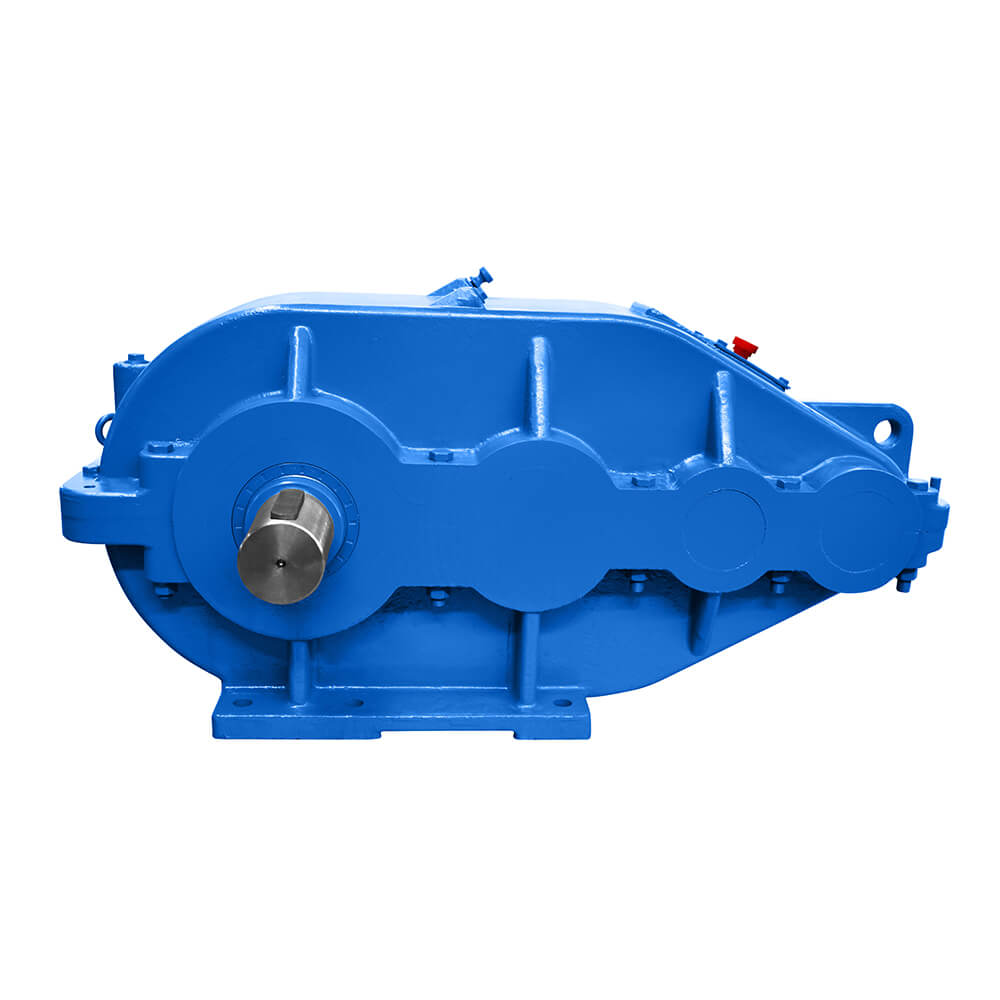

l Vertical Compact Design

Adopting a vertical mounting structure, it occupies a small footprint and effectively utilizes vertical space.

Particularly suitable for transmission systems with height restrictions or requiring vertical layouts.

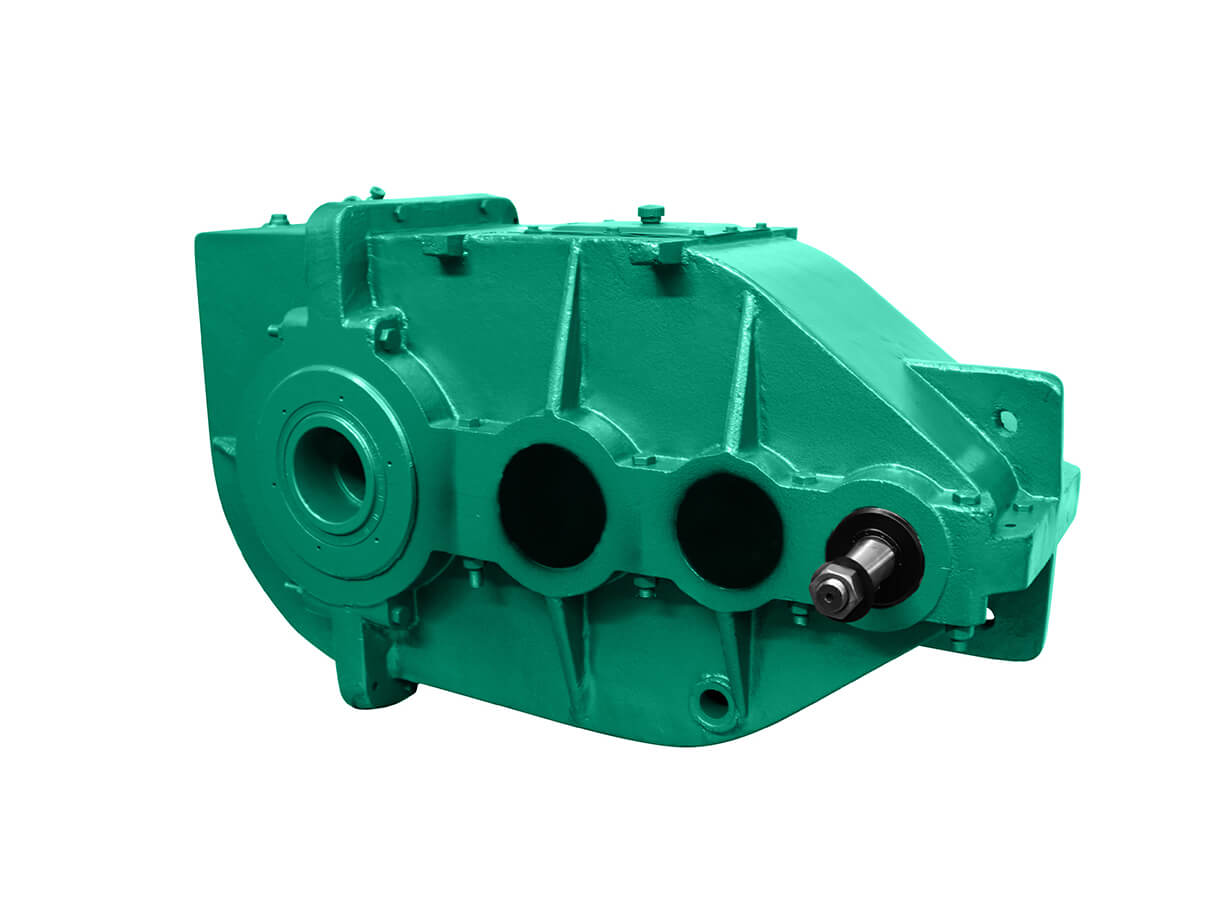

l Three-stage transmission system

Achieving a wide transmission ratio range through three-stage gear reduction, it provides low output speed and moderate output torque.

l Reliable transmission components

Gears are made of high-quality alloy steel and tempered to create a soft tooth surface.

Excellent wear resistance and impact resistance.

l Sturdy housing

Adopting a high-strength cast iron housing ensures precise gear meshing.

Smooth operation with low vibration and noise.

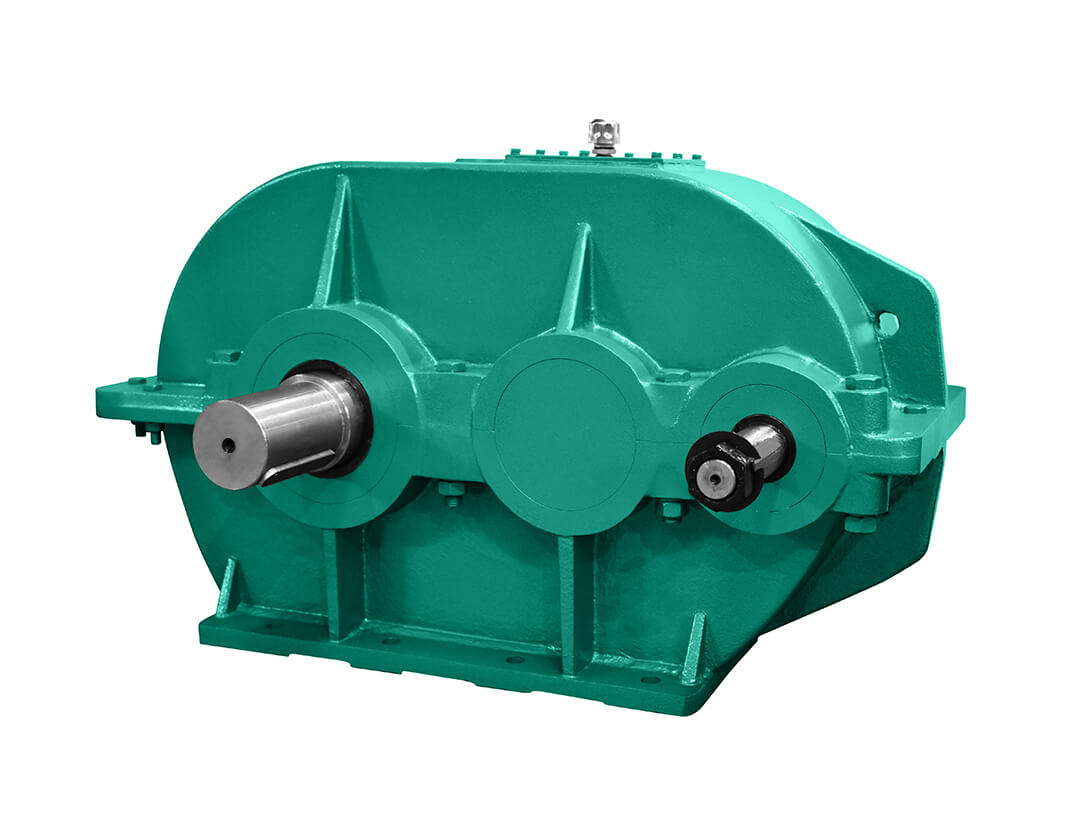

Differences between the ZSC and ZSC(A) series

Comparison Dimensions | ZQ Series Gearboxes | ZQD Series Gearboxes |

Product Positioning | Basic models meet general operating requirements | Optimized and upgraded models offer more reliable performance |

Load Capacity | Standard load capacity | Higher load capacity for more demanding operating conditions |

Gear Strength | Standard gear design | Optimized gear parameters for increased strength |

Applicable Operating Conditions | General industrial applications | Higher-demand industrial environments |

Mounting Compatibility | Standard mounting dimensions | Mounting dimensions are essentially the same as the ZSC series, making it easy to replace |

Cost-Effective | Economical and practical | Improved performance and overall value |

Selection Tips: While maintaining mounting dimensions compatible with the ZSC series, the ZSC(A) series achieves improved performance through optimized gear parameters and improved manufacturing processes. It is an ideal choice for users seeking higher reliability and longer service life.

Typical Applications

Hoisting and Transportation Equipment: Tower Crane Slewing Mechanisms, Construction Hoisting Machinery

Metallurgical and Mining Machinery: Steel Rolling Auxiliary Equipment, Mine Hoists, Feeders

Building Materials Equipment: Cement Mixing Plants, Brick and Tile Machinery

General Industrial Applications: Various Machinery and Equipment Requiring Vertical Drives

Selection Guide

When choosing a ZSC or ZSC(A) series reducer, please consider the following factors:

1. Operating Requirements: For general applications, the ZSC series is sufficient; for more demanding applications, the ZSC(A) series is recommended.

2. Output Parameters: Determine the required output torque, output speed, and motor power.

3. Installation Space: Confirm the installation location and space limitations.

4. Environmental Conditions: Consider the operating environment's temperature, humidity, and dust levels.

Why Choose Our ZSC/ZSC(A) Series Reducers?

We offer a complete ZSC series product line, including basic and upgraded models, to meet the diverse needs of our customers. With a strict quality control system and a dedicated technical support team, we ensure that each reducer delivers reliable performance and a long service life.

Please contact our technical team to provide you with the most suitable vertical reducer solution!