WS-9120 is a high-performance, fully automatic computerized wire processing machine that integrates precise cutting and multi-function stripping. It features an advanced servo and stepper drive system and a user-friendly 7-inch true-color touchscreen for intuitive operation. Designed to handle a wide range of conductors from 10 to 120 mm²

WS-9120 Automatic Wire Cutting Stripping Machine

PRODUCT DESCRIPTION

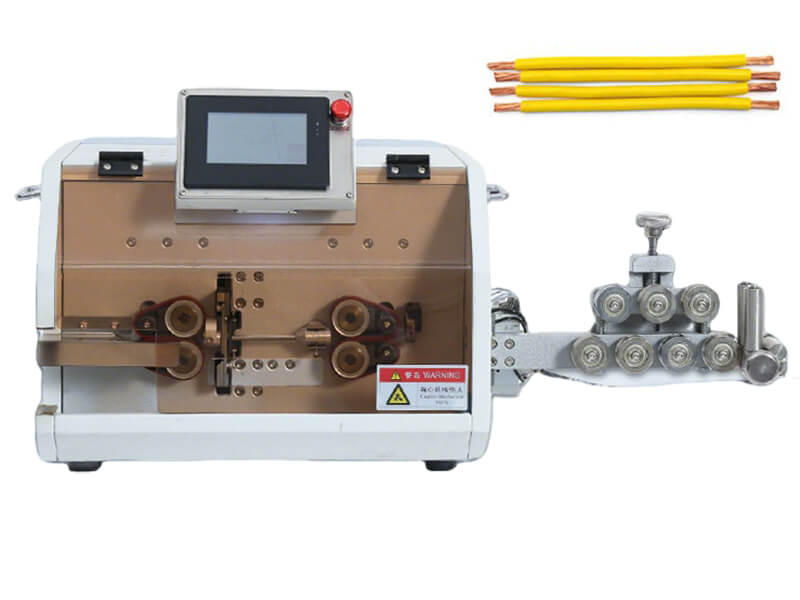

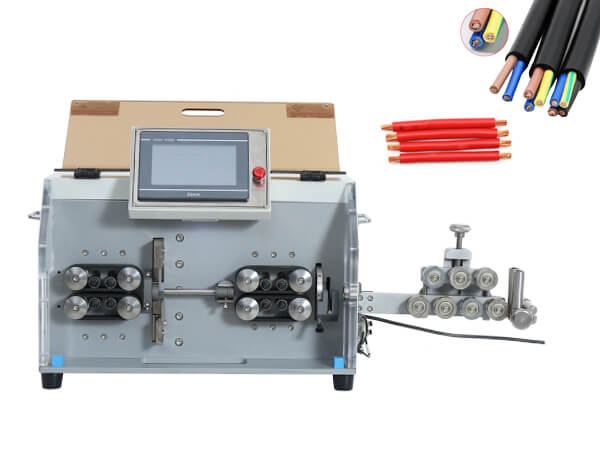

The WS-9120 is a high-performance, fully automatic computerized wire processing machine that integrates precise cutting and multi-function stripping. It features an advanced servo and stepper drive system and a user-friendly 7-inch true-color touchscreen for intuitive operation. Designed to handle a wide range of conductors from 10 to 120 mm², including single-core wires, multi-core cables, and shielded wires, it is a reliable solution for efficient and high-precision wire harness processing.

FEATURES

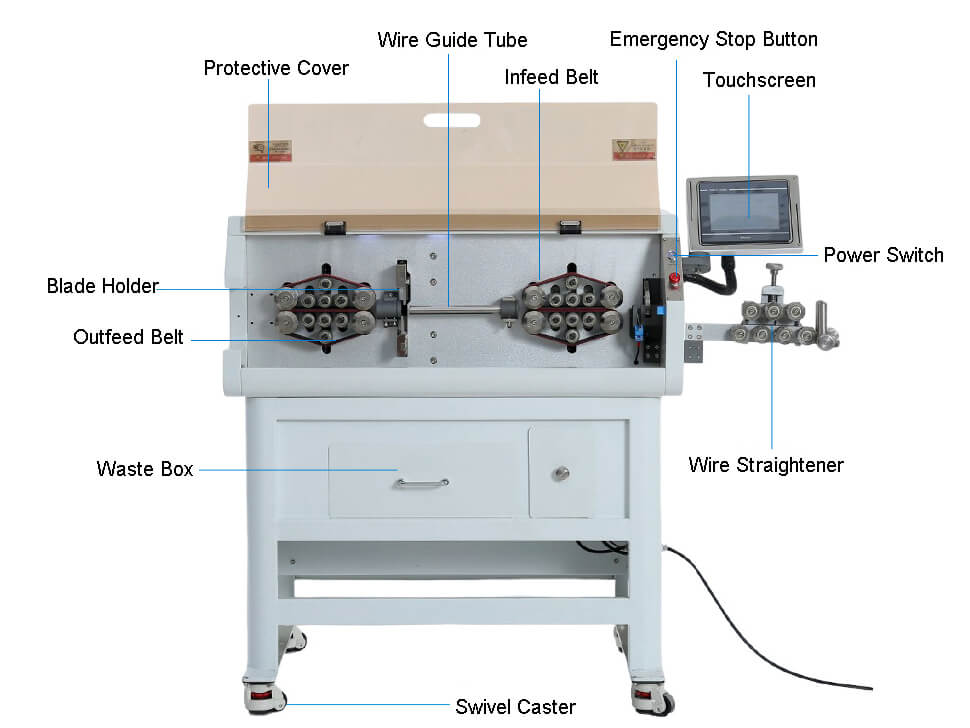

l High-Precision Processing: Utilizes a "24-roller servo/stepper drive" and "belt feeding" system to ensure mark-free and scratch-free wire conveyance. The cutting length tolerance is within ±0.002×L, guaranteeing accurate fixed-length cutting.

l Versatile Stripping: Supports both full-strip and semi-strip modes for wire front and rear ends, meeting complex wire processing requirements.

l Wide Compatibility: Handles wire sizes from 10 to 120 mm² with a maximum outer diameter of Φ25mm, suitable for various materials including PVC.

l Efficient Production: Theoretical maximum productivity reaches 800 cycles/hour. Combined with large program storage capacity (e.g., 99 sets), it allows quick switching between different wire processing programs, significantly boosting batch operation efficiency.

l Reliability & Durability: The core cutting blades are made of high-quality imported high-speed steel, ensuring long-term sharpness, stability, and low failure rates.

TECHNICAL SPECIFICATIONS

Model | WS-9120 |

Wire Types | Single-core, Multi-core Cable, Shielded Cable, PVC, etc. |

Display | 7-inch True-color Touchscreen |

Stripping Range | 10 - 120 mm² |

Max. Wire Diameter | Φ25 mm (Guide Tube Size: φ25/20/15/10mm) |

Cutting Length | 1mm - 99999.99mm |

Length Tolerance | ≤ 0.002 × L (L = Cutting Length) |

Stripping Length | Front strip: 1-800mm Rear strip: 1-400mm |

Blade Material | High-quality High-Speed Steel |

Drive Method | 24-roller Drive (Stepper Feeder, Servo Cutter) |

Feeding Method | Belt feeding, no indentations or scratches |

Productivity | 800-1000 PCS/Hour (depending on length and wire size) |

Roller Lifting Method | Stepper Motor Lifting |

Guide Tube Swinging | Pneumatic Cylinder |

Power Supply | AC 220V 50/60Hz 1.5KW |

Air Supply | 0.5-0.7Mpa |

Weight | 270kg |