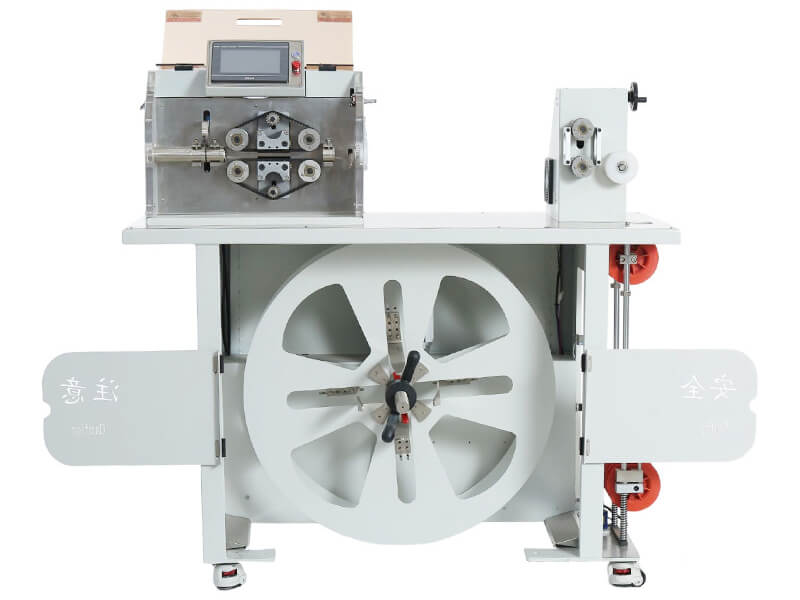

AC-330F is an innovatively designed, integrated, floor-standing fully automatic tube cutting solution. It moves beyond the traditional separated setup of a “cutter plus a standalone feeder” by integrating three core functions—large-capacity tube payout, automatic feeding, and precision cutting—into a single machine.

AC-330F Floor-Standing Automatic Cutting Machine

PRODUCT DESCRIPTION

AC-330F is an innovatively designed, integrated, floor-standing fully automatic tube cutting solution. It moves beyond the traditional separated setup of a “cutter plus a standalone feeder” by integrating three core functions—large-capacity tube payout, automatic feeding, and precision cutting—into a single machine. Users can directly place large coils or bundles of tubing (e.g., corrugated conduits) into the built-in storage area, and the integrated feeding system automatically handles advancing and cutting. This significantly saves space, equipment investment, and operational complexity, making it the ideal choice for modern workshops pursuing efficient, continuous production.

FEATURES

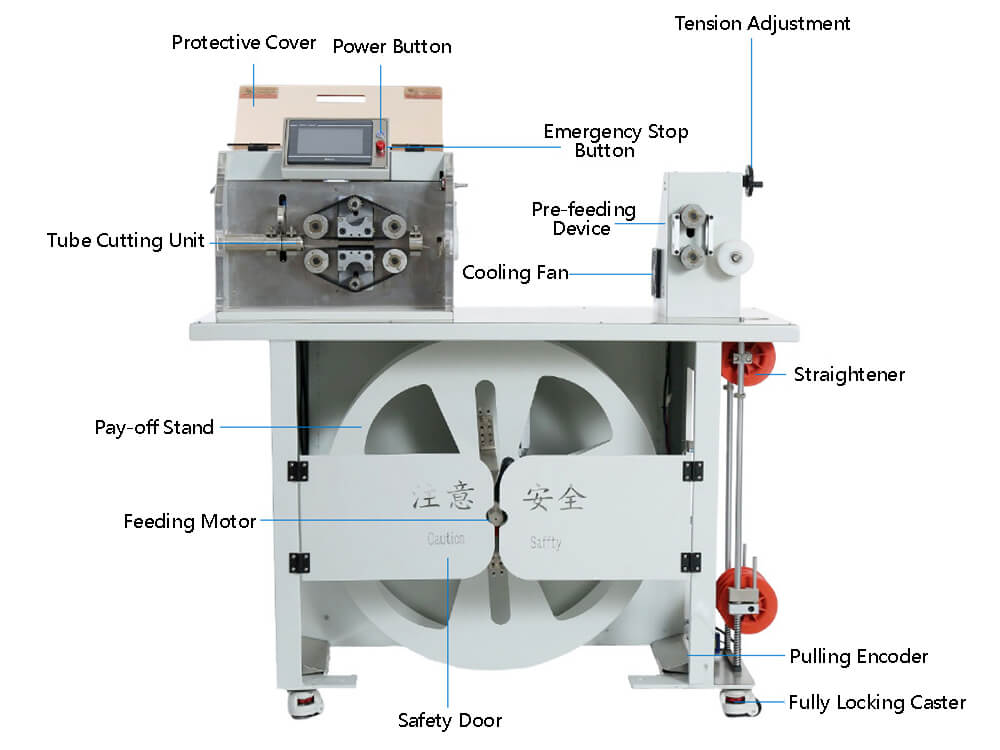

1. All-in-One Integration, Saves Space and Effort: As a floor-standing integrated unit, its primary advantage is the built-in complete tube payout and feeding system. There is no need to purchase and interface a separate feeding machine, simplifying equipment layout, saving valuable production floor space, and eliminating inter-machine calibration.

2. High-Capacity Automatic Feeding: Equipped with an inverter motor-driven intelligent payout system capable of handling and automatically feeding large bundles or coils of tubing. The feeding speed is smoothly adjustable, minimizing manual intervention and enabling extended periods of continuous automated production, ideal for large-volume orders.

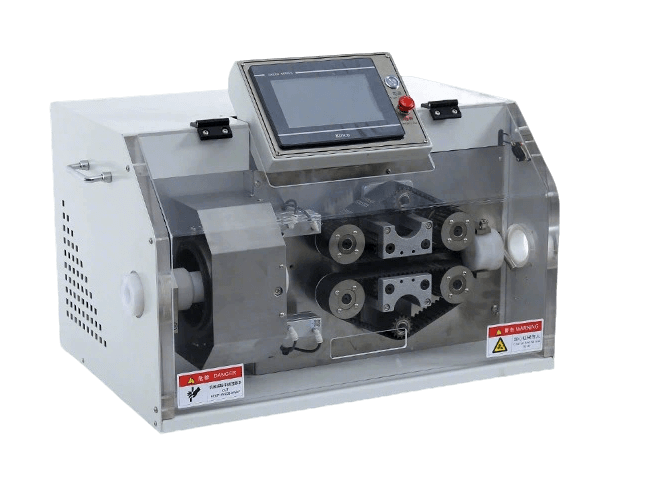

3. Powerful and Efficient Cutting: Powered by a high-torque 1100W drive motor, ensuring sufficient and stable cutting force even during continuous operation with integrated feeding. It easily handles various tubes within the ø5 to ø30mm range while maintaining clean cut quality.

4. Intelligent and User-Friendly Control: Utilizes a centralized PLC and HMI control system. The cutting length can be precisely set within a wide range from 0.1mm to 99999.9mm. All feeding and cutting parameters can be intuitively set and monitored on the same interface for easy management.

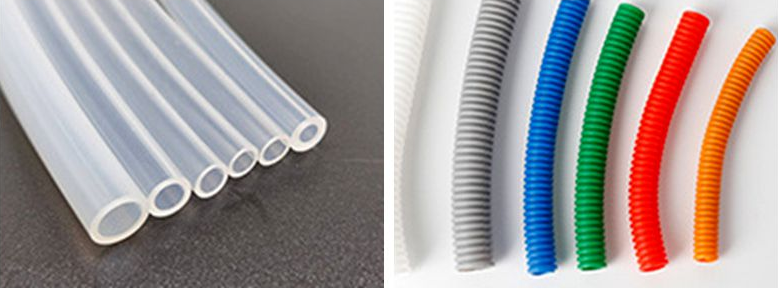

SUITABLE MATERIALS

Designed for applications requiring continuous, high-volume processing of coiled tubing. Particularly suitable for the cutting stage in automated production lines for industries such as automotive wire harness conduits, appliance drain pipes, and network communication cable conduits. It is a key piece of equipment for wire harness factories, tubing distributors, and large component manufacturers looking to enhance overall automation and production efficiency.

TECHNICAL SPECIFICATIONS

Model | AC-330F |

Control System | PLC + HMI Touchscreen Interface |

Cutting Method | Motor Direct-Drive Cutting |

Payout&Feeding System | Inverter Motor + Controller |

Power Supply | AC 220V 50/60Hz |

Power | 1100W |

Cutting Diameter | ø5 - ø30mm |

Cutting Length Range | 0.1 - 99999.9mm |

Length Tolerance | ±1% |

Cutting Speed | 10 - 60 pcs/min (depending on length) |

Dimensions | L1400*W670*H1400mm |

Weight | Approx. 180kg |