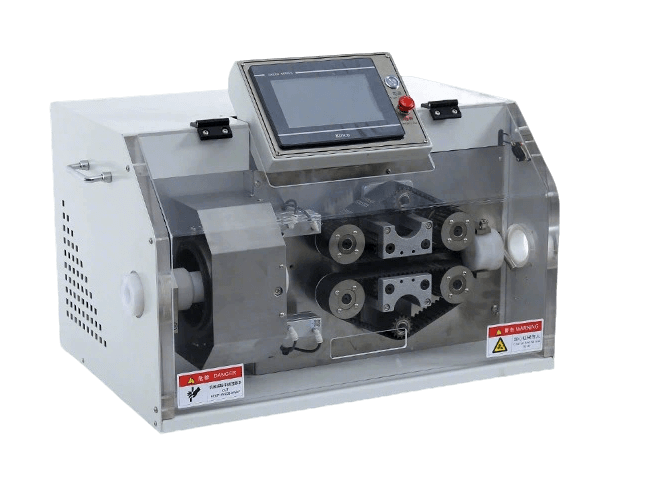

The AC-330X is a professional-grade, fully automatic tube cutting machine representing a profound innovation based on a mature platform. This model revolutionizes the traditional vertical cutting method by innovatively adopting a servo-driven precision rotary cutting head, resulting in smoother cutting action and exceptionally clean, burr-free cuts.

AC-330X High-Precision Rotary Cutting Machine

PRODUCT DESCRIPTION

The AC-330X is a professional-grade, fully automatic tube cutting machine representing a profound innovation based on a mature platform. This model revolutionizes the traditional vertical cutting method by innovatively adopting a servo-driven precision rotary cutting head, resulting in smoother cutting action and exceptionally clean, burr-free cuts. While retaining the core intelligence of PLC control, it features comprehensive upgrades to its power and drive systems. It is specifically engineered for high-end tube processing applications with stringent requirements for cut quality, precision, and efficiency, making it particularly suitable for handling various plastic and thin-walled tubes of differing hardness.

FEATURES

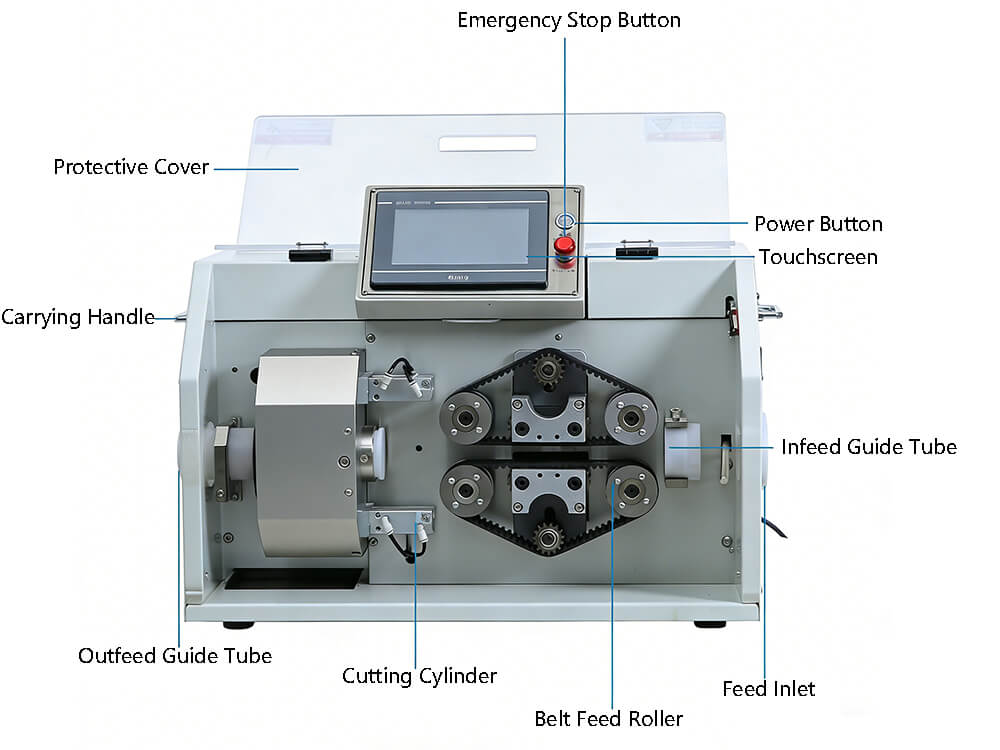

1. Servo Rotational Cutting Technology: Equipped with a high-response 400W servo motor driving a specially designed rotary blade, it utilizes a "chip-free shearing" principle instead of traditional punching. The cutting process offers low resistance and noise, producing flat, smooth cuts without deformation or crushing of the tube end, significantly enhancing finished product quality.

2. Ultra-Precision Digital Control: The combination of a "Digitally Adjustable Clamping" system, high-precision stepper motor feeding, and servo-driven rotation achieves exceptional dimensional stability. It delivers industry-leading accuracy with a length tolerance of L×0.001±0.2mm (for PVC tubes with L<1000mm), meeting the strict demands of precision assembly.

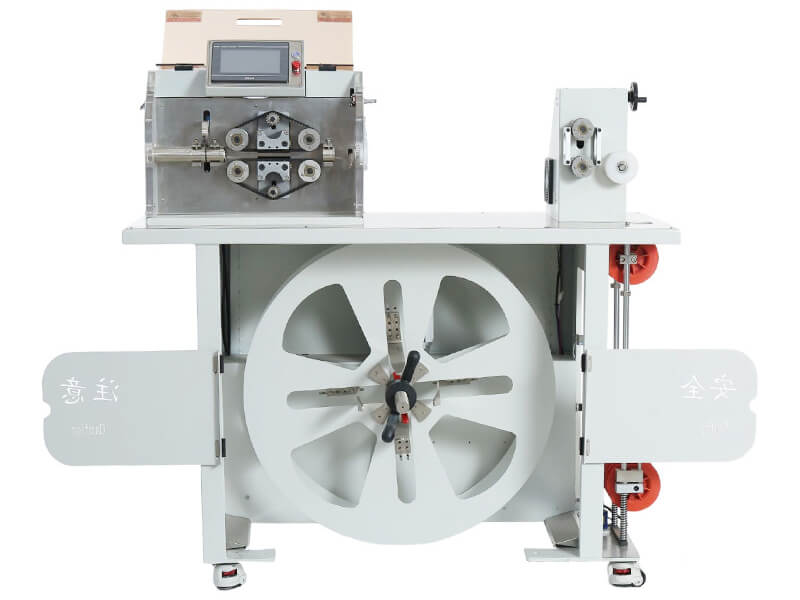

3. Efficient and Wide-Range Processing Capability: The total system power is increased to 750W. Combined with an optimized mechanical structure (8mm cutting stroke), it enables stable and efficient processing of tubes within a broader diameter range from ø5mm to ø42mm. With a maximum cutting speed of up to 60 pieces/minute, it offers strong adaptability and high output efficiency.

4. Intelligent and Stable Operation: It continues to employ the reliable PLC and HMI touchscreen interface control system, allowing digital setting and monitoring of all parameters (pressure, length, speed). The added pneumatic assistance function (requires 0.5-0.7 Mpa air supply) ensures more stable tube clamping and feeding.

SUITABLE MATERIALS

Ideal for the fixed-length cutting of various tubes requiring high-quality finishes and precise dimensions, including PVC tubes, PU tubes, silicone tubes, heat shrink tubing, PTFE tubes, and many other plastic flexible tubes. It is perfectly suited for high-end manufacturing fields such as automotive fluid lines, medical device catheters, precision pneumatic tubing, and appliance wire harness conduits.

TECHNICAL SPECIFICATIONS

Model | AC-330X |

Control System | PLC + HMI Touchscreen Interface |

Core Cutting Method | Servo Motor-Driven Rotational Cutting |

Feeding System | Stepper Motor Precision Feeding |

Tube Clamping Method | Digitally Adjustable Clamping |

Rotary Motor | 400W Servo Motor |

Power Supply | AC 220V 50/60Hz |

Power | 750W |

Air Supply | 0.5-0.7 Mpa |

Cutting Diameter | ø5 - ø42mm |

Length Tolerance

| Length Tolerance ≤ L×0.001±0.2mm (e.g., for PVC tubes with L<1000mm) |

Cutting Speed | 10 - 60 pcs/min (depending on length) |

Dimensions | L540*W560*H570mm |

Weight | 70kg |